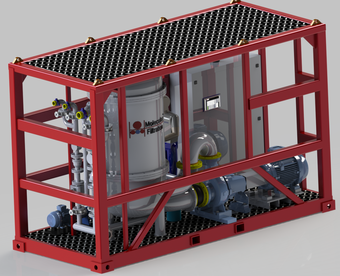

A new frontier in filtration, deep at the molecular level,

like no filtration has been done before.

From non-polar molecules to viruses.

Molecular filtration technology comes to help the new frontier in filtration.

Ceralumoxane™ - Membranes - Unstoppable Organic Rejection

Ceralumoxane™ membranes are manufactured using the "top‐down" approach.

This represents a departure from the traditional synthetic methodologies of the "bottom‐up" approach, which is, the reaction of small inorganic molecules to form oligomeric and polymeric materials, and subsequently nanoparticles which is a common approach for a wide range of metal and non‐metaloxides.